MOULD CONSTRUCTION

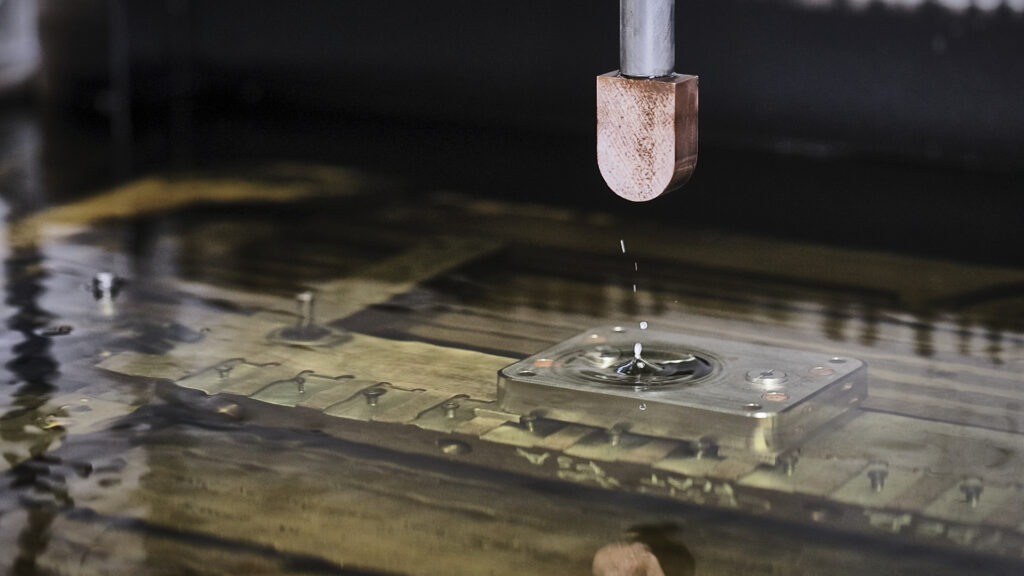

We build steel moulds of all shapes and sizes up to 25 tonnes with specific machining operations such as milling, EDM and deep hole drilling. All CNC control centres are supported by dedicated CAM software, which automates the creation of tool paths for high quality results.

30 YEARS EXPERIENCE

Over the years, our machine park has been constantly renewed.

Today there are 5-axis machining centres equipped with CNC. All operators are trained in the use of CAM software, for individual management of tool paths and to ensure total turnover.

Our machine shop is divided into several departments: milling, deep drilling, EDM, wire EDM, adjusting, polishing and laser welding. In fact, we are equipped to carry out each project in its entirety.

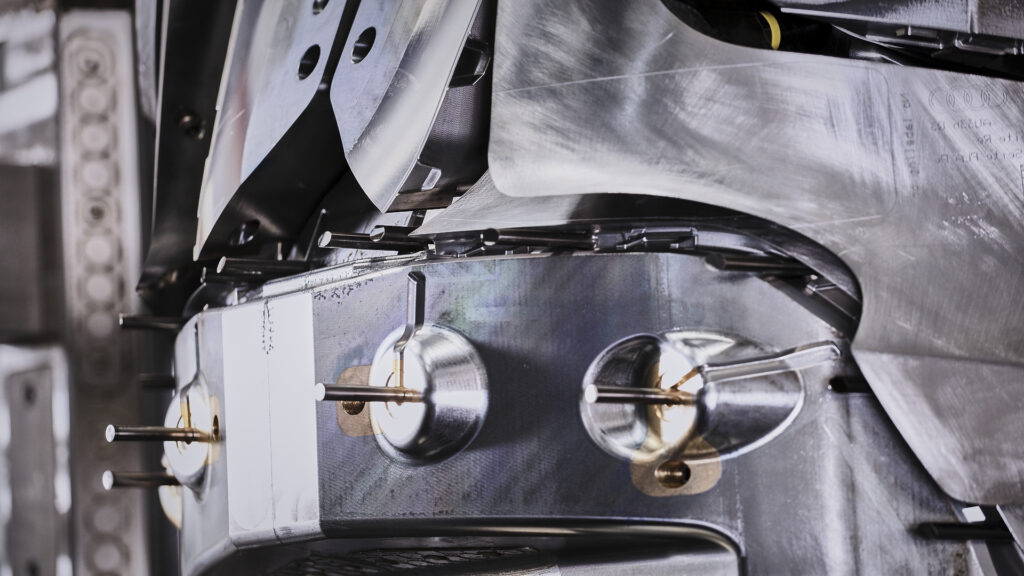

STACK MOULD INJECTION SYSTEM

The ‘sandwich’ injection system (stack mold) is ideal for multiplying production from the same injection moulding machine. Building moulds with this technology allows us to guarantee the quality of the final product by increasing production and keeping prices down.

BABY MOULDS

Thanks to our baby moulds, we also produce plastic parts of a few millimetres, which undergo continuous quality control to ensure a high degree of precision.

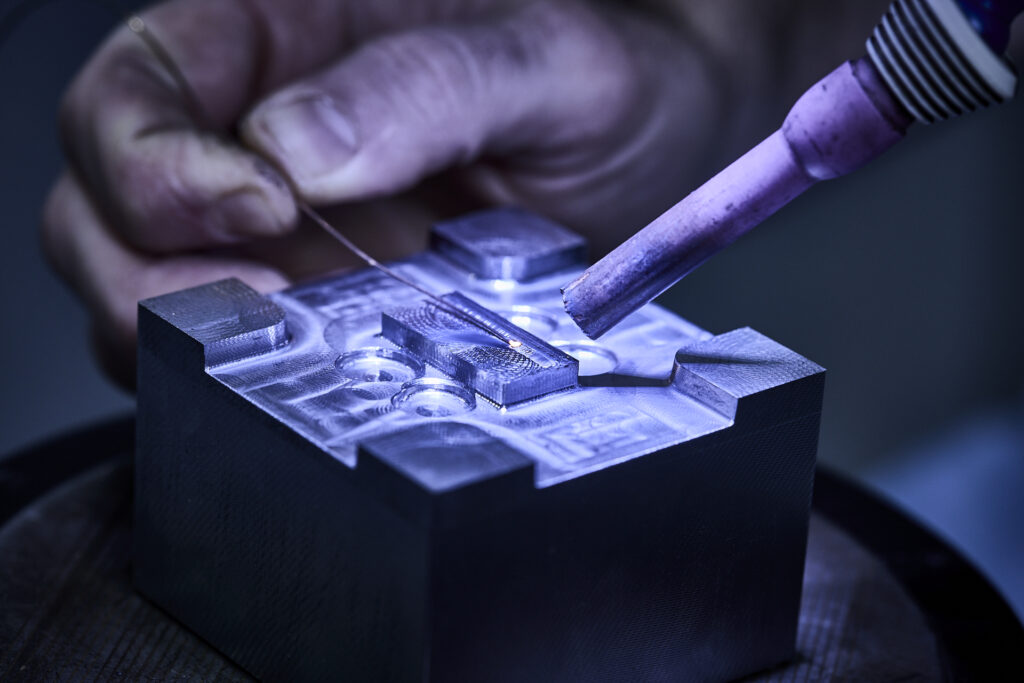

MANUAL PROCESSING

To guarantee our customers a complete service in mould construction, we take care of the manual adjustment of all mould components, polishing and laser welding in-house.

We also perform maintenance services on existing moulds at the request of our customers.